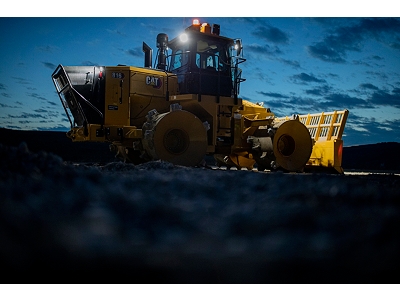

816 Landfill Compactor

Cat Landfill Compactors are designed with durability built in, ensuring maximum availability through multiple life cycles. With optimized performance and simplified serviceability, our machines allow you to operate more efficiently ...

Engine

- Gross Power - SAE J1995:2014

- 284hp

- Net Power - SAE J1349:2011

- 249hp

- Net Power - ISO 9249:2007

- 249hp

- Engine Power - ISO 14396:2002

- 275hp

- Engine Model

- Cat® C7.1

- Emissions

- Option 1 - U.S. EPA Tier 4 Final/EU Stage V/Korea Stage V and Japan 2014

- Rated Speed

- 2200

- Peak Torque ( 1,400 rpm )

- 902lbf·ft

- Torque Rise

- 52%

- Note

- Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, aftertreatment, and alternator.

- Emissions

- Option 2 - Brazil MAR-1, emitting equivalent to U.S. EPA Tier 3/EU Stage IIIA

- Rated Speed

- 2200

- Net Power - SAE J1349:2011

- 249hp

- Net Power - ISO 9249:2007

- 249hp

- Gross Power - SAE J1995:2014

- 286hp

- Engine Power - ISO 14396:2002

- 275hp

- Peak Torque ( 1,400 rpm )

- 749lbf·ft

- Torque Rise

- 26%

- Note

- Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, muffler, and alternator.

- Bore

- 4.1in

- Stroke

- 5.3in

- Displacement

- 427.8in³

- High Idle Speed

- 2270r/min

- Low Idle Speed

- 800r/min

- Maximum Altitude - Without Derating

- 9842.5ft

Operating Specifications

- Operating Weight (Tier 4 Final/Stage V)

- 57345lb

- Operating Weight (Tier 3/Stage IIIA equivalent)

- 56793lb

Transmission

- Transmission Type

- Cat Planetary Power Shift

- Travel Speeds - Forward - First

- 3.4mile/h

- Travel Speeds - Forward - Second

- 5.3mile/h

- Travel Speeds - Reverse - First

- 3.7mile/h

- Travel Speeds - Reverse - Second

- 5.5mile/h

Hydraulic System - Lift/Tilt

- Lift/Tilt System - Circuit

- Pilot operated LS valve with EH

- Lift/Tilt System

- Variable displacement piston

- Maximum Flow at 2,200 rpm

- 23.5gal/min

- Relief Valve Setting - Lift/Tilt

- 3190psi

- Cylinders, Double Acting: Lift, Bore, Stroke

- 120 mm x 915 mm (4.7 in x 36.0)

- Pilot System

- Open center, fixed displacement gear

- Pilot Relief Valve Setting

- 3046psi

Hydraulic System - Steering

- Steering System - Circuit

- Pilot, Load Sensing

- Steering System - Pump

- Piston – Variable Displacement

- Maximum Flow at 2,200 rpm

- 38.8gal/min

- Relief Valve Setting - Steering

- 4003psi

- Total Steering Angle

- 84°

- Steering Cycle Times - High Idle

- 3s

- Steering Cycle Times - Low Idle

- 8.2s

Service Refill Capacities

- Fuel Tank

- 132.1gal (US)

- Diesel Exhaust Fluid Tank

- 4.2gal (US)

- Cooling Systems - Tier 4 Final/EU Stage V

- 21.4gal (US)

- Cooling System - Tier 3/Stage IIIA Equivalent

- 19.3gal (US)

- Engine Crankcase

- 5.3gal (US)

- Transmission

- 14.8gal (US)

- Differential - Final Drives - Front

- 11.4gal (US)

- Differential - Final Drives - Rear

- 11.4gal (US)

- Hydraulic System - Implement/Steering

- 46.2gal (US)

- Hydraulic Tank Only

- 19.8gal (US)

- Note

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: • 20% biodiesel FAME (fatty acid methyl ester) * • 100% renewable diesel, H

Air Conditioning System

- Air Conditioning

- The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf. See the label or instruction manual for identification of the gas. - If equipped with R134a (Global Warming Potential = 1430), the system co

Axles

- Front

- Planetary – Fixed

- Rear

- Planetary – Oscillating

- Oscillation Angle

- ±6°

Braking System

- Service Brakes

- Single Disc Wet (Enclosed) 2 WHL

- Parking Brake

- Drum and Shoe, Spring Applied, Hydraulic Released

Sound Performance - Tier 4 Final / Stage V

- Operator Sound Pressure Level (ISO 6396:2008)

- 72dB(A)

- Machine Sound Power Level (ISO 6395:2008)

- 111dB(A)

- Operator Sound Pressure Level (ISO 6396:2008)*

- 70dB(A)

- Machine Sound Power Level (ISO 6395:2008)*

- 109dB(A)

- Note (1)

- * Sound suppression equipped

- Note (2)

- The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at maximum engine cooling fan speed.

- Note (3)

- The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at maximum engine cooling fan speed.

- Note (4)

- Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

Sound Performance - Tier 3 / Stage IIIA

- Operator Sound Pressure Level (ISO 6396:2008)

- 72dB(A)

- Machine Sound Power Level (ISO 6395:2008)

- 112dB(A)

- Operator Sound Pressure Level (ISO 6396:2008)*

- 70dB(A)

- Machine Sound Power Level (ISO 6395:2008)*

- 110dB(A)

- Note (1)

- * Sound suppression equipped

- Note (2)

- The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at maximum engine cooling fan speed.

- Note (3)

- The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at maximum engine cooling fan speed.

- Note (4)

- Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.

Straight Blade

- Capacity

- 13.08yd³

- Overall Width

- 12ft

- Height

- 6.4ft

- Height of Cutting Edge

- 3.2ft

- Digging Depth

- 1.2ft

- Ground Clearance

- 3.7ft

- Turning Radius – Outside Corner of Blade

- 21.2ft

- Turning Radius - Inside Corner of Blade

- 9.5ft

- Weight

- 4548lb

- Total Operating Weight

- 57345lb

Wheels

- Combination Tips (Weight Group)

- 13554lb

- Plus Tips - Weight (Group)

- 13982lb

- Paddle Tips - Weight (Group)

- 13126lb

- Outside Diameter

- 67.6in

- Drum Diameter

- 55.1in

- Drum Width

- 40in

- Tips per Row

- 5

- Tips per Wheel

- 20

- Replaceable

- Weld On

- Width Over Drums

- 131.4in

- Tip Height

- 6.25in

Dimensions (Approximate)

- Height - Top of Beacon

- 14.3ft

- Height to Top of Air Conditioning Condenser

- 13.7ft

- Height - Cab Roof

- 12.7ft

- Height - Top of Exhaust Pipe

- 11.6ft

- Height - Top of Hood

- 9.1ft

- Height to Top of Rear Compactor Guard

- 8.2ft

- Ground Clearance to Hitch

- 1.7ft

- Ground Clearance to Bottom of Bumper

- 2.7ft

- Centerline of Rear Axle to Bumper

- 6.5ft

- Centerline of Rear Axle to Rear Compactor Guard

- 8.6ft

- Hitch to Centerline of Front Axle

- 5.5ft

- Wheel Base

- 11ft

- Width over Front Striker Bars

- 9.8ft

- Width over Rear Striker Bars

- 10ft

- Width over Platform

- 10.3ft

- Width over Drums

- 11ft

- Overall Machine Length with Straight Blade

- 25.6ft

- Ground Clearance to Transmission Guard

- 1.7ft

OPERATOR COMFORT AND CONTROL

- Improved ingress/egress with a totally redesigned cab with flip up armrest.

- Keep your operators informed about machine conditions and operation with VIMS™ 3G machine monitoring system.

- Safety and visibility enhanced with standard rearview camera.

- Preferred temperature settings maintained with automatic climate control.

- Operator productivity enhanced with new membrane switch panels, keyed ignition, and E-H parking brake switch.

- Improved comfort with low operator sound levels.

- Improved spectator sound levels and optional low sound packages.

TOP-TIER SERVICE AND SUPPORT

- Easier access and in a controlled environment; electronics bay is located inside the cab.

- Focused on safety with ground level or platform access to most major components.

- Ground level: emergency shutdown, battery disconnect, and jump start.

- Quick visual inspection and minimize fluid contamination with sight gauges for coolant, transmission, and hydraulic oil.

- Electronic air inlet restriction indicator.

- Designed for ease of service and inspection.

– Hydraulic oil cooler, fuel cooler, and condenser grouped together

– Centralized grease points - Operators and technicians can resolve any problems before failure using Vital Information Management System (VIMS).

POWERFUL EFFICIENCY

- Reliable performance, long life, low emissions.

- High productivity and fuel efficient.

- Two engine options available that meet U.S. EPA Tier 4 Final and EU Stage V emission standards or U.S. EPA Tier 3 and EU Stage IIIA equivalent.

- For the Tier 4 Final and Stage V option, the Cat Clean Emissions Module contains a diesel oxidation catalyst, diesel particulate filter, and Cat Regeneration System, utilizing SCR technology.

- Regeneration is completely automatic and does not interrupt the machine’s work cycle.

- Experience maximum responsiveness and control with Steering and Transmission Integrated Control System (STIC™).

- Conserve more fuel with the automatic engine and electrical system shutdown.

- Achieve greater momentum on grades and fuel savings by carrying that momentum through the shift points with the all new Advanced Productivity Electronic Control System (APECS) transmission controls.

- Operators experience less fatigue with throttle lock to maintain engine speed.

PRODUCTIVITY WITH TECHNOLOGY

- Compact technology combines advanced compaction measurement, in-cab guidance, and reporting capabilities to help you consistently meet compaction targets fast, uniformly, and in fewer passes – saving on fuel and the cost of unnecessary rework.

-Optional 3D mapping system available - Link technology (standard) provides access to machine location, hours, fuel consumption, idle time, events, and diagnostic codes through the online VisionLink® interface.

- Compact technology combines advanced compaction measurement, in-cab guidance, and reporting capabilities to help you consistently meet compaction targets fast, uniformly, and in fewer passes – saving on fuel and the cost of unnecessary rework.

WHEEL TIPS BUILT TO PERFORM

- Designed specifically to complement Cat machines.

- Improves machine performance through longer wear life and maintaining traction.

- Three wheel and tip configurations are available to meet your

- particular application:

1) Paddle Tip – High performance and less fuel burn with more traction and less weight.

2) Plus Tip – Traditional design for increased side slope stability.

3) Combination Tip – Both paddle and plus tips provide the best compromise of performance and fuel economy with side slope stability.