CB7

The Cat® CB7 Asphalt Compactor offers enhancements that simplify operation, provide versatility, and deliver excellent fuel economy. Rotary dials, oscillatory vibration, and 360º seating make this compactor a perfect match ...

Weights

- Operating Weight - With Cab

- 19588lb

- Standard Operating Weight with ROPS

- 19015lb

- Maximum Operating Weight with Cab

- 20404lb

- Maximum Operating Weight with ROPS

- 19834lb

Operating Specifications

- Standard Compaction Width

- 59in

- Maximum Compaction Width

- 65in

- Static Linear Load - With Cab

- 172lb/in

- Static Linear Load - With ROPS/FOPS

- 168lb/in

- Travel Speed - Maximum

- 7mile/h

Dimensions

- Overall Length

- 179in

- Overall Width

- 78in

- Height - With ROPS/FOPS or Cab

- 118in

- Wheel Base

- 130in

- Drum Diameter

- 44in

Engine

- Engine Model

- Cat® C3.6

- Engine Power (1)

- 100hp

Vibratory System

- Drum Width

- 59in

- Centrifugal Force per Drum - Maximum

- 17602lb

- Centrifugal Force per Drum - Minimum

- 11982lb

- Nominal Amplitude - High

- 0.026in

- Nominal Amplitude - Low

- 0.012in

- Vibration Selection

- Independent per drum, front only, rear only, both

Service Refill Capacities

- Fuel Tank Capacity

- 36gal (US)

- Water Spray Tank Capacity

- 195gal (US)

Simple to Operate, Comfortable, Easy to Learn

- Large, full-color displays keep the operator informed of machine functions including water and fuel levels, impact spacing, and mat temperature.

- Innovative hand-wheel steering technology delivers precise control and good forward visibility.

- Easily activate the vibratory system, water spray system and optional drum offset with the multi function propel handle.

- Machine functions with LED indicators have been independently grouped for simplified control and quick activation.

- Rotary dials with green light indicators provide a quick visual reference and fingertip feel for easy adjustment to speed control and water spray timers.

- ROPS and Cab options deliver excellent comfort and visibility. The cab option offers heat and air conditioning as standard equipment.

Work Safer with Enhanced Visibility

- Optional top down, 360º viewing utilizes cameras mounted in each corner of the ROPS for good work-zone visibility. This option utilizes a high definition display mounted to a swivel on the upper left side of the ROPS/Cab.

- Optional fore and aft cameras mounted in the front and rear bumpers provide good visibility when approaching obstacles. The camera view is integrated into the main operating display.

- Optimize sight lines with the 360º seating option; always face the direction of travel.

- LED lighting delivers excellent job site illumination while conserving energy. Strategically placed lighting illuminates the sides of the machine, drum surfaces, and drum edges.

- A green-light beacon mounted on the ROPS/Cab provides indication of seat belt utilization. Beacon illumination can be tailored to "ON" or "OFF" when in compliance.

Easy Vibratory System Setup

- Two-amplitude/two frequency vibratory system automatically optimizes amplitude and frequency with a single switch for simple thin/thick lift operation.

- Reach compaction goals with automatic speed control; green indicators help ensure travel speed matches the correct impact spacing.

- The automatic vibratory on/off feature activates or deactivates the vibratory system according to the propel lever position to help prevent over compaction when changing direction or when coming to a stop. The system is adjustable through the "Job Aids" menu in the display.

- Built-in application profiles can be created and saved to offer quick, repeatable setup for vibratory frequency, propel mode, impact spacing, water spray timer, and water spray mode.

- Edge management options include an edge cutter wheel that vertically slices the asphalt for easy removal to enhance joint matching capability, while bevel options provide sloped edge profiles.

- Front and rear split drum options simplify manueverability in tight spaces. When turning, the outside drum half rotates faster than the inside drum half to help prevent tearing and shoving of the asphalt.

Better Fuel Economy

- The C3.6 engine delivers 74.4 kW (100 hp) of power and meets U.S. EPA Tier 4 Final and EU Stage V emission standards.

- The Cat® C3.6 engine and standard Eco-mode combine to provide good fuel economy.

- Eco-mode modifies engine speed based on load requirements; high amplitude vibration utilizes higher engine speeds, while static rolling conserves fuel and operates at low engine speed with lower sound levels.

Ensure Mat Coverage with Compaction Control

- Pass-count and Temperature Mapping combines infrared temperature sensors with GPS mapping to keep the operator informed of current asphalt temperatures, machine position, pass-count, and layer coverage. The mapping display provides an enhanced on-screen visual for easy recognition and touchscreen capability for simplified setup.

- Compaction Meter Value (CMV) utilizes a drum mounted accelerometer to measure the combined stiffness of the asphalt layer, base layer, and sub-base layer to indicate road structure quality beneath the surface.

Prevent Build-Up, Keep the Drum Surfaces Wet

- The high capacity water tank with dual fill ports provides long durations between refills. An optional step can be mounted to the left-side rear drum support to assist with refills.

- Dual water pumps provide back-up capability and alternate with the direction of travel to maximize service life.

- Triple filtration helps prevent clogs with filters located at the fill point, water pumps, and spray nozzles.

- The automatic on/off feature deactivates the water spray system when the propel lever moves to neutral and activates the system when the propel lever moves from neutral. System setup is located in the "Settings" menu. A simple rotary dial provides adjustable spray settings and intermittent modes that help conserve water.

- The integrated freeze protection kit (optional) provides protection in cold temperatures when the machine is not in use.

Compaction Options Include Oscillation

- Oscillatory vibration on the rear drum combined with standard vertical vibration on the front drum delivers both performance and versatility.

- The Oscillation System utilizes the proven pod style eccentric weight technology developed by Caterpillar.

- A 2 year/2000 hour service interval helps maximize uptime and limit maintenance costs.

- A durable power transmission belt delivers 2-times the load capacity of timing belt systems, leading to extended life.

- Standard drum shells offer exceptional long-term life on a variety of mix designs while delivering outstanding mat texture, density, and smoothness.

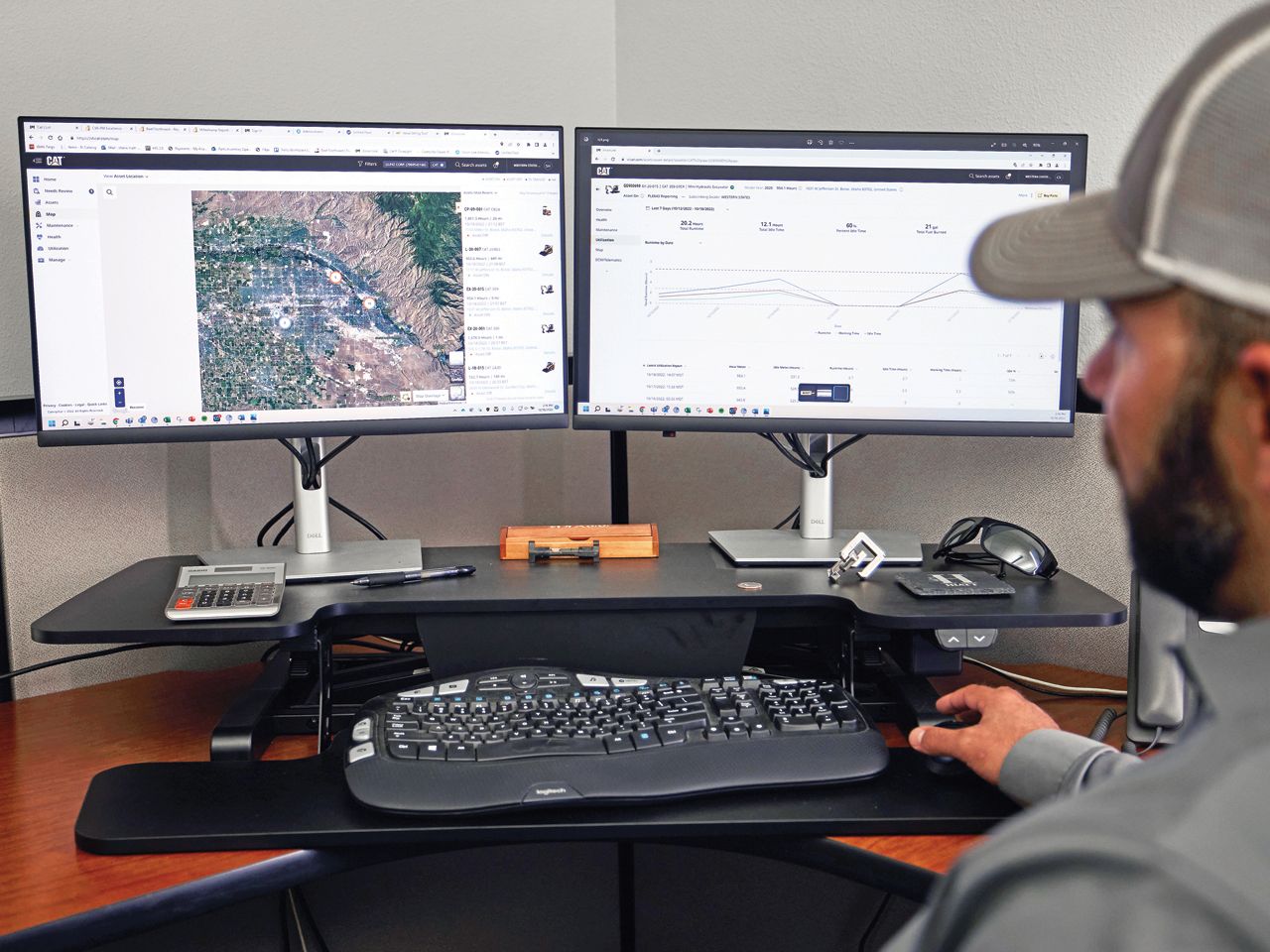

VisionLink®

- VisionLink® is a cloud based software application that provides data to your desktop or mobile device, taking the guesswork out of fleet management with key insights to maximize performance – regardless of fleet size or equipment manufacturer.

- The system provides maintenance needs, machine hours, location, fuel usage, idle time, diagnostic codes, and other machine data to your mobile device, desktop or through an API to other software applications.