260 Skid Steer Loader

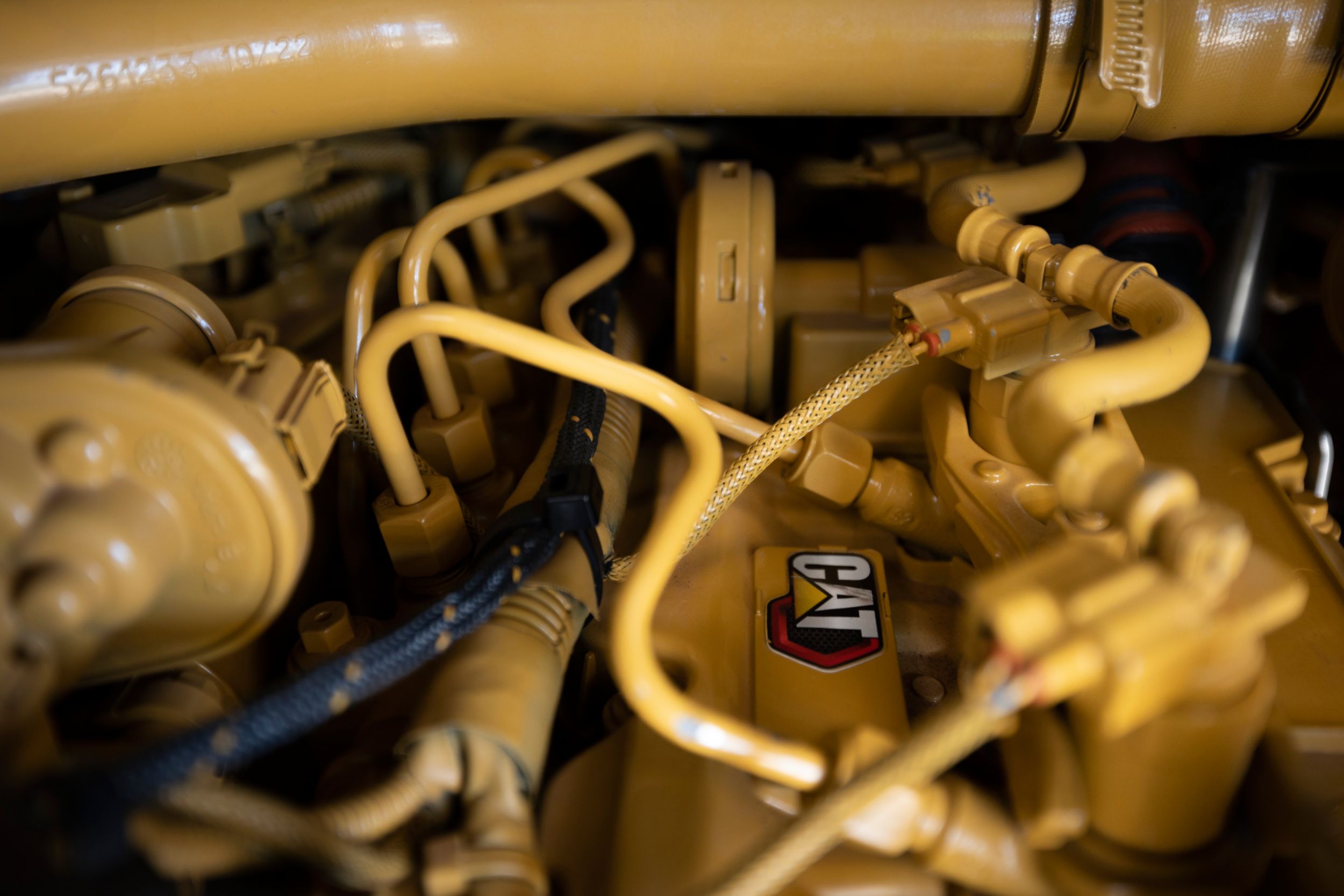

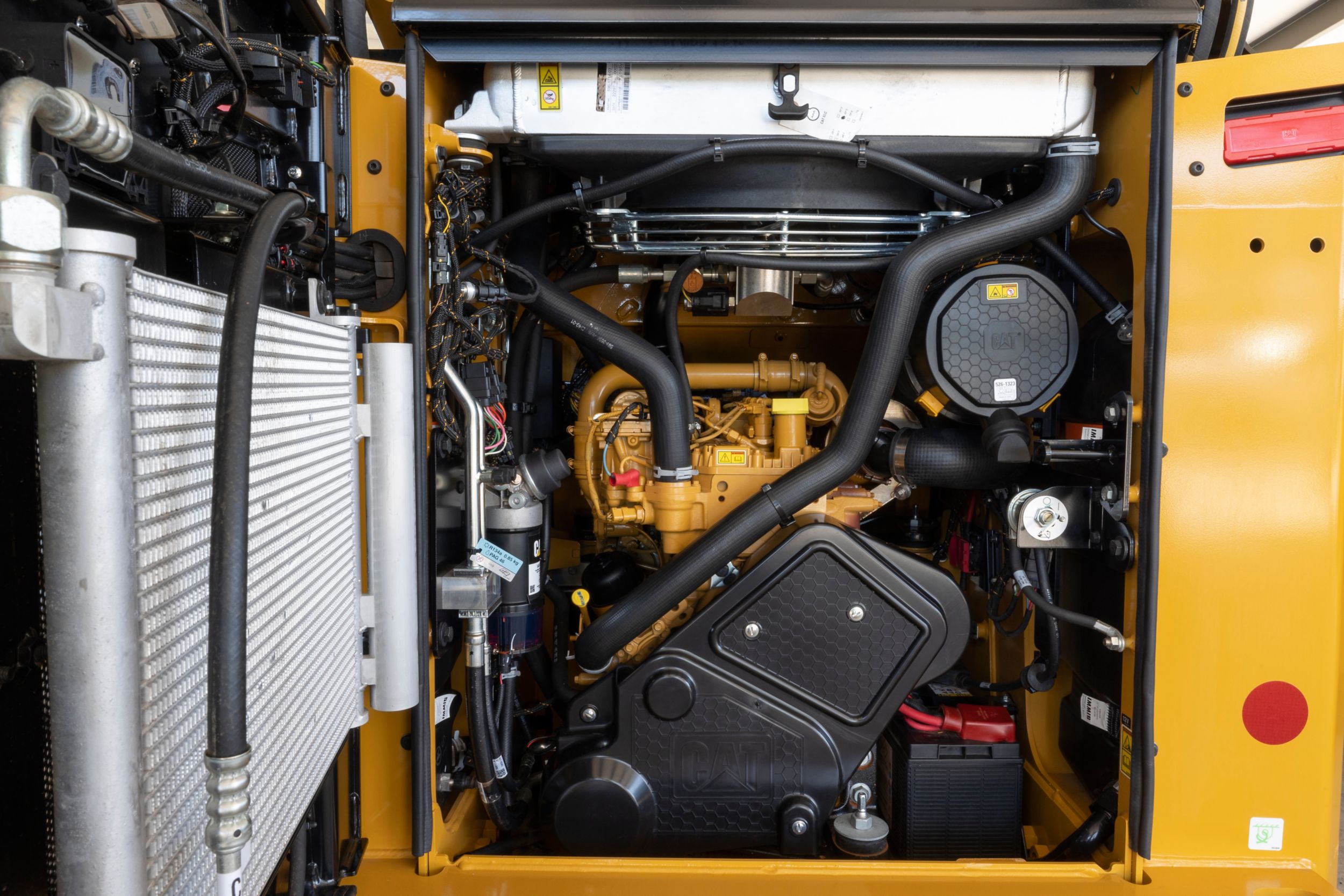

Engine

- Gross Power - SAE J1995:2014

- 74hp

- Net Power - SAE 1349

- 74hp

- Displacement

- 171in³

- Stroke

- 4.3in

- Bore

- 3.5in

- Note

- Advertised power is tested per the specified standard in effect at the time of manufacture. Net power advertised is the power available at the flywheel when the engine is equipped with fan at minimum speed, air intake system, exhaust system, and alternato

- Peak Torque - 1,600 rpm - SAE J1995

- 221lb/ft

- Net Power - ISO 9249

- 73hp

- Engine Model

- Cat C2.8T (turbo)

Operating Specifications

- Rated Operating Capacity

- 3160lb

- Tipping Load

- 6321lb

- Breakout Force - Tilt Cylinder

- 9372lb

- Breakout Force - Lift Cylinder

- 5948lb

- Rated Operating Capacity with Optional Counterweight

- 3388lb

- Note

- Operating Weight, Operating Specifications and Dimensions all based on 75 kg (165 lb) operator, all fluids, one speed, OROPS (Open Roll Over Protection System), 1730 mm (68 in) low profile bucket, Cat 12 × 16.5 tires, standard flow hydraulics, mechanical

Weights

- Operating Weight

- 8523lb

- Note

- Operating Weight, Operating Specifications and Dimensions all based on 75 kg (165 lb) operator, all fluids, one speed, OROPS (Open Roll Over Protection System), 1730 mm (68 in) low profile bucket, Cat 12 × 16.5 tires, standard flow hydraulics, mechanical

Dimensions

- Wheel Base

- 49.2in

- Height - Top of Cab

- 81.9in

- Vehicle Width over Tires

- 66.5in

- Ground Clearance

- 7.9in

- Departure Angle

- 23°

- Maximum Dump Angle

- 46°

- Bucket Pin Height - Maximum Lift

- 132.5in

- Bucket Pin Height - Carry Position

- 8in

- Clearance at Maximum Lift and Dump

- 96.2in

- Maximum Overall Height

- 155.8in

- Length - With Bucket on Ground

- 135in

- Note

- Operating Weight, Operating Specifications and Dimensions all based on 75 kg (165 lb) operator, all fluids, one speed, OROPS (Open Roll Over Protection System), 1730 mm (68 in) low profile bucket, Cat 12 × 16.5 tires, standard flow hydraulics, mechanical

- Turning Radius from Center - Bucket

- 82.7in

- Bucket Pin Reach - Maximum Lift

- 12.6in

- Maximum Reach - With Arms Parallel to Ground

- 44.1in

- Length - Without Bucket

- 116.4in

- Reach - Maximum Lift/Dump

- 21.7in

- Turning Radius from Center - Coupler

- 53.8in

- Turning Radius from Center - Machine Rear

- 71.8in

- Roll Back Angle

- 28°

- Rack Back Angle - Maximum Height

- 97°

Cab

- ROPS

- ISO 3471:2008

- FOPS

- ISO 3449:2005 Level I

- FOPS Level II

- ISO 3449:2005 (Optional)

Service Refill Capacities

- Chain Box - Each Side

- 2.4gal (US)

- Cooling System

- 3gal (US)

- Engine Crankcase

- 2.1gal (US)

- Fuel Tank

- 31gal (US)

- Hydraulic System

- 9.7gal (US)

- Hydraulic Tank

- 6.9gal (US)

Hydraulic System

- Hydraulic Flow - Standard - Loader Hydraulic Pressure

- 3335psi

- Hydraulic Flow - High Flow - Hydraulic Power (Calculated)

- 58hp

- Hydraulic Flow - High Flow XPS - Maximum Loader Hydraulic Flow

- 34gal/min

- Hydraulic Flow - Standard - Loader Hydraulic Flow

- 20gal/min

- Hydraulic Flow - High Flow - Maximum Loader Hydraulic Flow

- 30gal/min

- Hydraulic Flow - High Flow - Maximum Loader Hydraulic Pressure

- 3500psi

- Hydraulic Flow - High Flow XPS - Maximum Loader Hydraulic Pressure

- 4061psi

- Hydraulic Flow - High Flow XPS - Hydraulic Power (Calculated)

- 80.7hp

- Hydraulic Flow - Standard - Hydraulic Power (Calculated)

- 39hp

Power Train

- Travel Speed - Forward or Reverse - One Speed

- 7.7mile/h

- Travel Speed - Forward or Reverse - Two Speed Option

- 11.1mile/h

Noise Level

- Note (1)

- Cab and Rollover Protective Structures (ROPS) are standard in North America and Europe.

- Note (3)

- **The labeled sound power level for the CE marked configurations when measured according to the test procedure and conditions specified in 2000/14/EC.

- Inside Cab*

- 83 dB(A)

- Note (2)

- *The declared dynamic operator sound pressure levels per ISO 6396:2008. The measurements were conducted with the cab doors and windows closed and at 70% of the maximum engine cooling fan speed. The sound level may vary at different engine cooling fan spee

- Outside Cab**

- 101 dB(A)

Air Conditioning System (if equipped)

- Air Conditioning

- The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 0.85 kg of refrigerant which has a CO2 equivalent of 1.216 metric tonnes.

Sustainability

- Recyclability

- 93%

High Performance Power Train

High performance power train provides maximum performance and production capability through the Electronic Torque Management system, optional two speed travel and an electronic hand/foot throttle with decel pedal capability.

Redesigned Operator Station

Redesigned operator station delivers a larger operating environment. Combined with additional seat travel, the 260 provides more space for operators of any size. The optional one-piece, sealed, and pressurized cab offers a clean and quiet workspace with excellent air distribution through optimally placed vents throughout the cab.

Ventilated and Heated High-Back Air Ride Seat

Available ventilated and heated high-back air ride seat with seat-mounted adjustable joystick controls deliver superior operator comfort.

Three Levels of Auxiliary Hydraulic Performance

Three levels of auxiliary hydraulic performance available, Standard Flow, High Flow, and High Flow XPS. Standard flow for attachments that require a base level of auxiliary flow and horsepower, High Flow boosts the auxiliary flow for applications that demand additional hydraulic flow for increased attachment performance, and the High Flow XPS hydraulic system provides maximum auxiliary hydraulic performance by delivering additional flow and additional pressure for the most demanding attachments and applications.

Electronically Controlled Cat C2.8T Engine

Electronically controlled Cat C2.8T engine meets U.S. EPA Tier 4 Final and EU Stage V emission standards while delivering maximum horsepower across a wide RPM range and providing high torque for increased working performance, no matter the application.

Ride Control

Speed sensitive ride control option improves operation on rough terrain, enabling better load retention, increased productivity, and greater operator comfort.

Advanced Touchscreen Monitor

The 20.3 cm (8-inch) Advanced Touchscreen Monitor offers cutting-edge functionality and control that includes an integrated radio, Bluetooth® connectivity, and multi-camera (side-view) option, and supports 32 different language choices.

Advanced Joysticks

The Advanced Joysticks provide unmatched control of machine functions and adjustments within the display without having to remove your hands from the controls. This includes on-joystick navigation of the Advanced Touchscreen Monitor, radio volume up/down/mute, creep activation, creep on/off, creep speed increment/decrement, one-button Smart Attachment control activation, and additional auxiliary control buttons that deliver single-button control of complex attachment functions.

Ground-Level Access

Ground-level access to all daily service and routine maintenance points helps reduce machine downtime for greater productivity.

Cat Attachments

Broad range of performance matched Cat Attachments make the Cat Skid Steer Loader the most versatile machine on the job site.