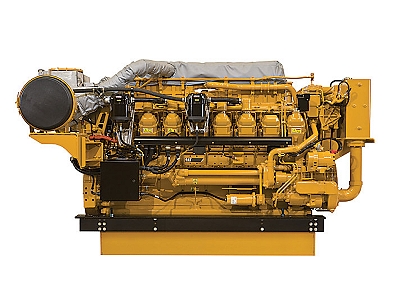

3516C

Power Rating

- Power Range

- 2000-3385 bhp (1492-2525 bkW)

Engine Specifications

- Speed Range

- 1200-1800 rpm

- Emissions

- IMO II

- Aspiration

- TTA

- Bore

- 8.46in

- Stroke

- 7.48in

- Displacement

- 4765in³

- Rotation from Flywheel End

- Counterclockwise or Clockwise

- Configuration

- V 16, 4-Stroke-Cycle Diesel

Dimensions & Weights

- Minimum Height

- 77.4in

- Minimum Length

- 143.1in

- Maximum Length

- 148in

- Maximum Width

- 84.3in

- Maximum Height

- 84.6in

Complete Solution for Your Marine Application'

• Single-source for support and service • Industry-leading warranty coverage for factory packaged components • Global dealer network for service in any location

Efficient Operation

• Instrument panel with cold mode start strategy and programmable low idle • Electronic governing control unit minimizes fuel consumption and monitors engine operating parameters • Optional alarm and protection system

Improved Performance and Function

• Standard marine twin turbocharger configuration. • More reserved power for superior part load performance at continuous ratings • Turbos tuned for high power and excellent fuel consumption

Environmentally Conscious

• Closed crankcase ventilation system and redesigned piston for improved efficiency and lower emissions • Optimal nozzle geometry and electronic injection control for improved fuel delivery • EPA Marine Tier 3/IMO Tier II Emissions Compliant