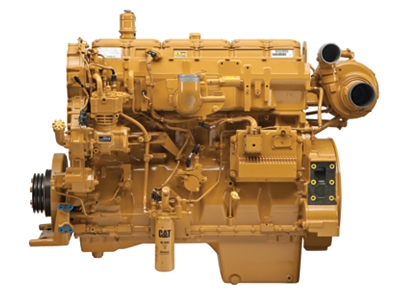

C15 ACERT Land Mechanical Drilling Engine

Cat C15 ACERT engines are the ideal solution for your demanding operations in the oilfield. Decades of field operation and intense research and development allow Cat C15 ACERT engines to

... deliver excellent performance with low operating costs and emissions. This is an ideal engine for land mechanical drilling applications such as mud pump drives. Cat C15 ACERT™ Industrial Diesel Engine. Ratings: 328-354 bkW (440-475 bhp) @ 1800 rpm meet China Stage II, U.S. EPA Tier 3 equivalent, EU Stage IIIA equivalent emission standards.

Engine Specifications

- Minimum Rating

-

440BHP

- Maximum Rating

-

595BHP

- Emissions

-

EPA and CARB Non-Road Mobile Tier 3, EU Stage IIIA

- Rated Speed

-

2100r/min

- Bore

-

5.4in

- Stroke

-

6.75in

- Displacement

-

928in³

- Aspiration

-

Turbocharged-Aftercooled

- Governor and Protection

-

ADEM A3

- Engine Weight - Net Dry

-

2743lb

- Rotation from Flywheel End

-

Counterclockwise

- Oil Change Interval

-

250

- Flywheel and Flywheel Housing

-

SAE No. 0 or SAE No. 1

- Flywheel Teeth

-

136 (SAE 0), 113 (SAE 1)

Capacity for Liquids

- Minimum Cooling System - Engine Only

-

5.5gal (US)

Dimensions

- Length

-

54in

- Width

-

37in

- Height

-

48in

Custom Packaging

For any petroleum application, trust Caterpillar to meet your project needs with custom factory generator sets and mechanical packages. Cat engines, generators, controls, radiators, and transmissions can be custom designed and matched in collaboration with our local dealers to create unique solutions. Custom packages are globally supported and are covered by a one year warranty after startup.

Custom Packaging

For any petroleum application, trust Caterpillar to meet your project needs with custom factory generator sets and mechanical packages. Cat engines, generators, controls, radiators, and transmissions can be custom designed and matched in collaboration with our local dealers to create unique solutions. Custom packages are globally supported and are covered by a one year warranty after startup.

Transmissions

Caterpillar has a full line of engine-transmission packages that can be fully integrated with your axle, hydraulics, and operator interface. Cat transmissions deliver continuous operation under full load, smooth shifting at any speed, and maximum up time, with unmatched durability and easy maintenance.

Full Range of Attachments

Large variety of factory-installed engine attachments reduces packaging time

Testing

Every engine is full-load tested to ensure proper engine performance.

Product Support Offered Through Global Cat Dealer

- More than 2,200 dealer outlets - Cat factory-trained dealer technicians service every aspect of your petroleum engine - Cat parts and labor warranty - Preventive maintenance agreements available for repairbefore-failure options - S•O•SSM program matches your oil and coolant samples against Caterpillar set standards

Over 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.

Over 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.

Web Site

For all your petroleum power requirements, visit www.cat.com/oilandgas.

Standard Equipment:

- Air Inlet System

-

- Single turbocharger, mid-mounted, inlet 152.4 mm (6 in), hose connection

- Control System

-

- Electronic governing, PTO speed control

- Programmable ratings

- Cold mode start strategy

- Automatic altitude compensation

- Power compensation for fuel temperature

- Programmable low and high idle and TEL

- Electronic diagnostics and fault logging

- Engine monitoring and protection system (speed, temperature, pressure)

- J1939 Broadcast (diagnostic, engine status, and control)

- Cooling System

-

- Thermostats and housing — outlet vertical

- Jacket water pump — gear-driven, centrifugal, RH

- RH front water pump inlet

- All plugs/fittings are STOR for lines gp water

- Exhaust System

-

- Exhaust manifold — dry

- Front turbo exhaust

- Full marmon connection, maximum load 10 kg for direct connection to turbo

- Flywheels And Flywheel Housings

-

- Fuel System

-

- MEUI system

- Fuel filter, secondary, mid-mount (LH 2 micron high performance)

- Fuel transfer pump, LH front

- Fuel priming pump, LH mid-mount

- Fuel sample valve, mounted on fuel filter base

- Lube System

-

- Crankcase breather — rear valve cover

- Oil cooler — RH

- Oil filter — RH

- Oil pan — front sump

- Oil filler — LH front

- Oil dipstick — LH front

- Oil pump

- Oil valve sampling — on oil filter base

- Mounting System

-

- Front support (shipping only)

- Power Take-offs

-

- Crankshaft pulley, 203.2 mm (8 in), 3 grooves 292.1 mm (11.5 in) 1 groove, all 15.9 mm (.63 in) width

- Hydraulic pump drive, SAE A, 11 tooth

- General

-

- Vibration damper

- Paint — Cat yellow

- Lifting eyes

- Automatic variable timing, electronic

- Electronic installation kit 70-pin connector (connectors, pins, sockets)

- Literature group owner and operator

- Mandatory Options

-

- Throttle position sensor

- Exhaust system — front or rear

- Flywheel housing or rear PTO

- Primary filter/water separator

Optional Equipment:

- Transmission Arrangement

-

- Transmission cooler

- Tool set

- Air Compressor

-

- Air chambers

- Air compressor governor

- Air Inlet System

-

- Air cleaners

- Precleaners

- Air lines

- Air inlet gasket

- Charging System

-

- Charging alternators

- Alternator mountings

- Alternator wiring

- Circuit breaker mountings

- Alternator belt guard

- Cooling System

-

- Radiator — installed

- Radiator — ship loose

- Fan drive f/u/w Caterpillar installed radiator

- Fan drives for customer-supplied radiators

- Fan height instructions

- Vee belts for customer-supplied radiators

- Aftercooler lines f/u/w Caterpillar installed radiator

- Rear-facing exhaust

- Aftercooler lines

- Suction fan adapters — attaches fan to fan pulley

- Blower fan adapter — attaches fan to fan pulley

- Blower fan

- Suction fan

- Fan belt tightener

- Coolant level sensor

- Dry charge coolant conditioners

- Dry charge coolant conditioner element

- Exhaust System

-

- Turbo exhaust connection

- Flexible fitting

- Elbows

- Flanges

- Dry elbow