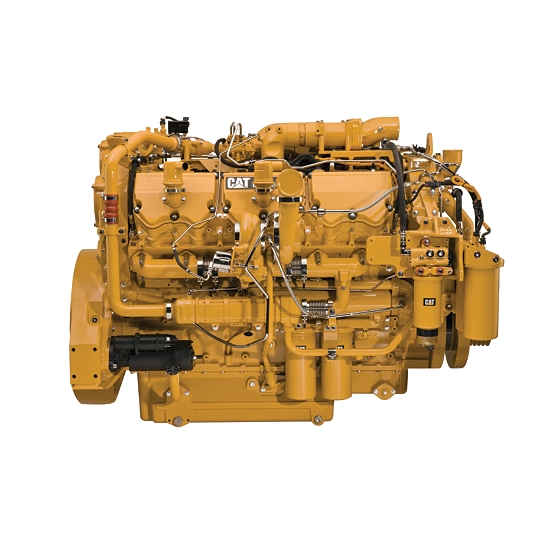

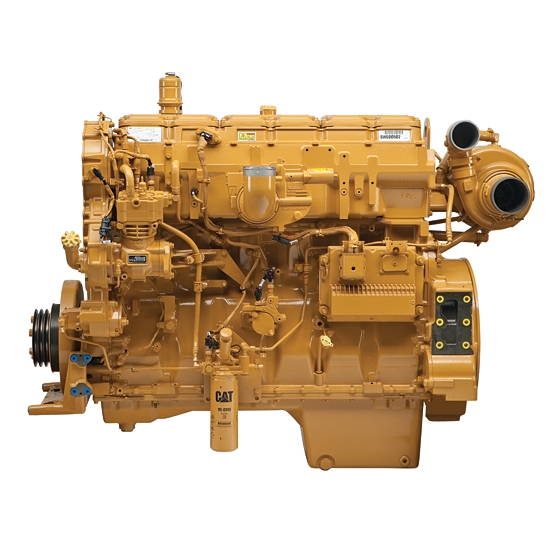

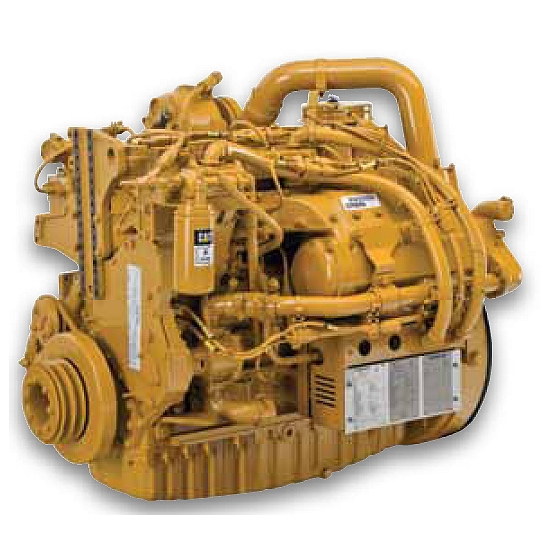

C9 ACERT™ Hazardous Location Engine

General Specifications

- Maximum Rating

- 340BHP

- Displacement

- 537.96in³

- Minimum Rating

- 325BHP

- Governor and Protection

- Electronic (ADEM™ A4)

- RPM

- 2200r/min

- Aspiration

- Turbocharged-Aftercooled

- Flywheel and Flywheel Housing

- SAE 1 or 2

- Flywheel Teeth

- 113 (SAE 1), 134 (SAE 2)

- Rotation from Flywheel End

- Counterclockwise

- Stroke

- 5.8in

- Bore

- 4.4in

Emissions

- Emissions

- EPA and CARB Non-Road Tier 3, EU Stage IIIA, EPA Marine Tier 2, IMO Tier II

Dimensions

- Length

- 43in

- Width

- 32.6in

- Height

- 40.3in

- Weight

- 1578lb

Capacity for Liquids

- Lube Oil System - Refill

- 8gal (US)

- Cooling System

- 3.7gal (US)

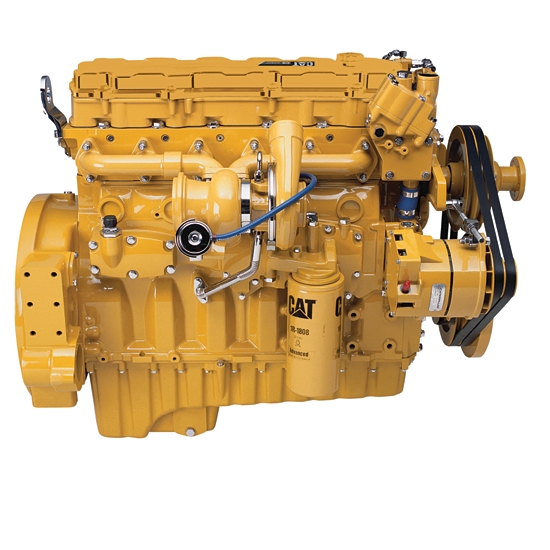

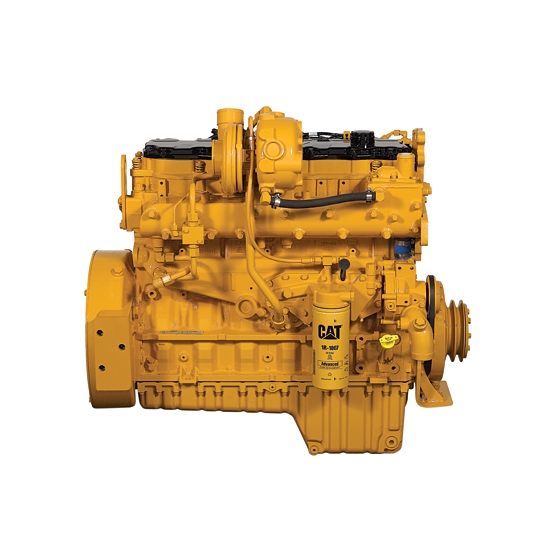

Engine Design

- Proven reliability and durability - 45°C ambient capability*- Robust diesel strength design prolongs life and lowers owning an operating costs- Broad operating speed range- PTO drive options provide flexible access to auxiliary power for pumps and other needs

Cat® Hazardous Location Engine

Cat Petroleum Hazardous Location Engines are third-party certified from Caterpillar- Class I Division 2 (NEC 500), - Class I Zone 2 (NEC 505), and - ATEX Directive (94/9/EC) Group II, 3G environments (Zone 2) with Gas Group IIA, Electrical IIC, and Temperature Class T3

Technology

- Electrical harness containing point-to-point wiring without splices in any power/signal wires- Electrical harnesses and connectors are overmolded and are routed through urethane tube for protection against impact and vertical flame propagation.- To meet safety requirements, connectors require the use of a special tool to be disconnected and bear the “do not disconnect while energized” warning.- Optional ATEX and NEC certified 25-foot customer harness- ECU is certified as part of the engine to restricted breathing per EN 60079-15. ECU is protected with a stainless steel guard.- Fuel injector connections at valve cover bases are protected with stainless steel guards

Advanced Digital Engine Management

ADEM A4 engine management system integrates speed control, air/fuel ratio control and ignition/detonation controls into a complete engine management system. control system with integrated digital ignition, engine protection and monitoring

Air System

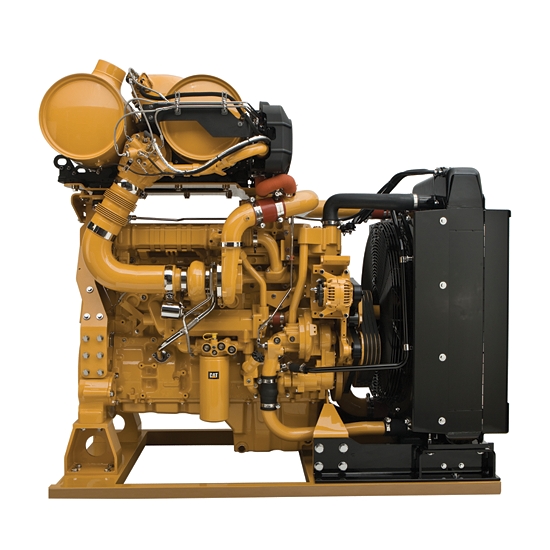

- Remote aftercooler (REMAC, air-to-air) and separate circuit (water-to-air) aftercooler options available to match any application requirement.- Water-cooled exhaust manifold and turbo maintain ATEXcompliant skin temperature during operation- Air Inlet shut-off enables emergency shut-off for operator safety

Improved Serviceability

- Front, right and rear dipsticks- Remote oil and fuel filters- 12V and 24V electronic systems to improve application flexibility

Transmissions

The full line of Cat engine/transmission packages can be fully integrated with your axle, hydraulics, and operator interface. Cat transmissions deliver continuous operation under full load, smooth shifting at any speed, and maximum up time, with unmatched durability and easy maintenance.

Custom Packaging

Trust a Cat factory custom package to meet your exact petroleum application needs. Cat engines, generators, enclosures, controls, radiators, transmissions — anything your project requires — can be custom designed and matched to create a one-of-a kind solution. Custom packages are globally supported and are covered by a one-year warranty after startup.

Full Range of Attachments

Large variety of factory installed engine attachments reduces packaging time

Testing

Every engine is full-load tested to ensure proper engine performance

Product Support Offered Through Global Cat Dealer Network

- More than 2,200 dealer outlets- Cat factory-trained dealer technicians service every aspect of your petroleum engine- Cat parts and labor warranty- Preventive maintenance agreements available for repair-before failure options- S•O•SSM program matches your oil and coolant samples against Caterpillar set standards

Over 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.- Cast engine blocks, heads, cylinder liners, and flywheel housings- Machine critical components- Assemble complete engine

Web Site

For all your petroleum power requirements, visit www.cat.com/oilandgas.