Choosing a power generation system is a big decision. Whether your power generating needs are temporary and supplemental to the established grid or intended to be a primary source of electricity, you need to choose a generator carefully and wisely. That comes from assessing your options of what’s available on the market. It’s also what best fits your particular application.

Jump To Sections:

- Factors in Choosing a Power Generation System

- Overview of Power Systems

- Renewable vs. Non-Renewable Resources and Power Systems

- Gasoline Power Systems

- Diesel Fuel Power Systems

- Natural Gas Power Systems

- Advantages and Disadvantages of Different Fuel Sources

- Comparing Performance in All Three Types

- Emerging Generator Technology

- Hybrid and Biofuel Generators

- Other Factors to Consider When Choosing a Power Generation System

- Consider Cat Your Power Generation System Provider

Choosing a generator from among the huge variety of options doesn’t have to be a difficult or stressful task. There’s a tremendous amount of information available. Unfortunately, much of it’s self-interested and doesn’t give you an objective and accurate look. That’s where an impartial guide to choosing a power generating system is invaluable.

Factors in Choosing a Power Generation System

Matching the right generator to your existing demands is crucial to successful operation. Output wattage size is vital. The particular brand name and model is important. So is the location where you’re operating your generator as well as climate factors and availability of service. Then you need to consider small details such as safety devices, displays, ease of maintenance, interface switches and, of course, the price.

All of these features and benefits form part of what you base your generator purchase decision on. They’re important to form the big picture. But almost always, one of the main criteria for choosing a power generation unit is the type of fuel required to power the generating engine. This decision is easy enough to overlook, but its significance is considerable.

Choosing a generator based on a predisposition or prejudice to one type of fuel alone can be misleading. There have been so many advancements in generator technology in recent years. What was true ten years ago might not be reliable fact today, especially in fuel. Perceptions that natural gas vs. a diesel generator is an inferior choice or that gasoline vs. a diesel engine has better economy can be wrong.

Overview of Power Systems

To guide you in making an informed choice when choosing a generator system, let’s first look at the heart of the generator. That’s the engine.

A power generation system is composed of two main parts. There’s the generating unit itself that makes and conducts electricity. That’s done on the principle of electromagnetism established for decades. There have been huge advances in improving armatures and coils integral to an electric generating field.

The second team member in a generating system is the engine that turns the rotor. With few exceptions, generator engines use the internal combustion system where fossil fuels are ignited inside sealed cylinders.

Renewable vs. Non-Renewable Resources and Power Systems

Fossil fuels are non-renewable resources. Unlike renewable resources such as wind, solar and water power that drive advanced and large electrical generation systems, fossil fuels are the number one choice for smaller residential, commercial and industrial generating systems. This includes permanent, stationary back-up generators as well as portable generating units.

All fossil fuels originated as the result of decaying organic compounds buried under the earth’s surface. Some fossil fuel deposits date back millions of years to when dinosaurs roamed the earth and huge ocean floors as well as surface jungles contained plants and animals. As they died and accumulated, the heat and pressure from natural action compressed these remnants. This changed their carbon structure, making them ideal energy sources for today’s internal combustion engines, including generators.

The three main fossil fuel sources for generator systems are gasoline, diesel fuel and natural gas. Each fuel type has pros and cons, which we’ll examine in a bit. First, it’s helpful to know what each fuel is so you can understand and weigh the advantages and disadvantages.

Gasoline Power Systems

Gasoline is also known as petroleum distillate or “petrol” in some countries. Gas is the most common fossil fuel for small engines, including passenger vehicles, light trucks and smaller electrical generator sets.

Gasoline is refined from crude oil and other petroleum products. According to the Energy Information Agency (EIA), refineries in the United States produce about 19 gallons of gasoline from every 42-gallon barrel of crude oil. Finished gasoline you buy at the pump comes in three octane, or quality, grades. These grades are rated as regular, midgrade and premium. The grades dictate the burn rate and anti-knock values of each type.

Gasoline used to contain lead to prevent pre-ignition, which is what caused the knocking sound from gas engines. Lead in gas was banned in 1975. Now other chemical properties are added to gasoline to make it perform better. Gasoline remains highly flammable and subject to fire.

Because gasoline is unstable as a liquid and vapor, it requires special storage and delivery systems for safety. It also has a different ignition method where it requires a spark. Gasoline engines utilize spark plugs and distributor systems for igniting this fuel inside an internal combustion engine. This presents some advantages of gas vs. diesel engines. Gasoline powered units present some disadvantages and safety concerns.

Diesel Fuel Power Systems

Rudolf Diesel was a German engineer who realized gasoline was undesirable due to its flammability at ambient or air temperature. Gasoline also burned hotter and caused more strain on moving engine parts. Diesel discovered another way to produce a crude oil-based fossil fuel that would not ignite by a spark. Rather it would combust at lower temperatures when mixed with air and highly compressed inside a specially designed internal combustion engine.

People have used diesel fuel for decades. It requires a different processing method that, according to the EIA, allows for 12 to 13 gallons of diesel fuel to be produced per barrel of crude oil. Diesel fuel is inherently stable when in an open environment and is much safer than gasoline under most conditions. It can’t be ignited by a spark like gas can. But it can be slowly burned with an open flame, which is why diesel fuel is sometimes used for heating oil.

When diesel fuel is compressed, it has different reactions. Inside an engine’s cylinders, diesel flashes into ignition at a much lower temperature and burns with much more energy efficiency than gasoline. This is called the flash point. With diesel, it’s 265 degrees Celsius, whereas with gasoline the internal flash point is 280 degrees Celsius. That’s why diesel engines run cooler than gasoline engines. It’s also why they’re known to run much longer.

The lower operating temperature of diesel engines has a clear advantage (compared to gasoline engines) besides exposing the moving parts to less heat, therefore less wear and tear:

- Diesel fuel combusts far more of its volume than gasoline. This makes the fuel efficiency function or energy density higher, which is why diesel engines are considered more fuel efficient.

- Also, because the ignition and full burn occur at lower temperatures and engine speeds, diesel engines are considered to have more lower-end power or torque.

Diesel engines have a nasty reputation for being noisy and dirty. This bad rap is somewhat undeserved in the face of new diesel engine technology. It’s one reason why the third type of fossil fuel is becoming increasingly popular. That’s natural gas.

Natural Gas Power Systems

Unlike gasoline and diesel fuel, which are liquids refined from crude oil, natural gas is exactly that. It’s a gas. Natural gas occurs deep in the earth. It’s also a fossil fuel that arrived in its present form through decay of organic compounds from plants and animals.

Natural gas is mainly composed of methane that chemically forms in a gaseous state unless it’s deeply compressed or chilled. In its natural form, methane mixes with sand and silt, forming huge deposits of fossil fuel that can be artificially fractured. This releases natural gas where it can be captured in wells, then pressurized into pipelines or cooled to be shipped in containers.

In raw form, natural gas is tasteless, colorless and odorless. It’s also highly explosive when exposed to air and can be set off by the slightest spark with the right air and fuel mixture. This is why an additive called mercaptan is processed into natural gas and gives its familiar warning smell described as rotten eggs.

Once natural gas burns, it has little waste or by-products other than water. That makes natural gas a clean-burning, popular choice in urban environments where air pollution is a problem. Natural gas also quickly dissipates once escaping from containment. That alleviates the mess from diesel and gasoline spills, which can be disastrous to clean up.

For these reasons, natural gas is the most economical and plentiful form of fossil fuel. It’s relatively easy to harvest and contain, and delivers excellent value as an energy source. According to the Energy Information Agency, Americans used 27.5 billion cubic feet of natural gas in 2015.

Natural gas is a main fuel supplier to the U.S electrical power grid. It’s also widely consumed for industrial, commercial, transportation and residential use as a heat source as well as powering internal combustion engines. That includes the engines on many stationary and portable electric generation systems.

There are a few other fuel options for powering electrical generators like propane or natural force energy sources such as wind and solar. But for your generator selection, you’re most likely to choose a conventional fossil fuel. It comes down to gasoline, diesel or natural gas.

Advantages and Disadvantages of Different Fuel Sources

Let’s now weigh the advantages and disadvantages of gasoline, diesel and natural gas engines when used on power generation systems. You’ll see some of the pros and cons overlap and outweigh each other, but this should help guide your choice.

Advantages of Gas Generators

Gasoline was the first fuel used in the invention and evolution of the internal combustion engine. It works on a system where raw, liquid gasoline vaporizes into a controlled air mixture through carburization or fuel injection. Once it’s enclosed in a combustion chamber, gasoline needs igniting by a spark. This requires spark plugs that are set off through an electro/mechanical distributor system.

Some of gasoline’s advantages are:

- Proven system that’s widely known and understood

- Ready and widely available fuel supply

- Works well with other gasoline-supplied machinery for fuel control

- Relatively good fuel economy

- Operates well in extreme climates, both hot and cold

- Relatively clean burning and low maintenance from fuel contamination

- Lower initial purchase price

- Inspires engines with more compact, lighter and versatile design

Some of gasoline’s disadvantages are:

- Highly flammable when exposed to air and a spark

- Unpredictability of fuel prices

- Hotter burning, causing more wear and tear on moving parts

- Lower energy density so less fuel economy

- Lower torque and power production at low speeds

- Less life span for engine components

- Higher depreciation rate and lower resale value

- Limits in the size of the unit and power output

Advantages of Diesel Generators

Diesel fuel was developed as a more stable and lower cost alternative to gasoline. Diesel engines do not have spark plugs or distributors to ignite the fuel, giving them less systematic parts and less that could go wrong. Liquid diesel fuel is injected directly into the combustion chamber, where the action of the valves and pistons mix the proper air-to-fuel ratio to a combustible volume. Diesel engines are the most popular and widely used power plant propulsion, for a number of good reasons.

Some of diesel’s advantages include:

- Very stable fuel from safety standpoint

- Excellent energy density and return for fuel economy

- Produces most power and torque at lower speeds

- Less wear and tear on moving parts

- Longer engine life

- More dependable performance

- Higher power outputs

- Heavier, better manufacturing materials and processes

- Lower depreciation and better resale value

- Plentiful supply of fuel

- Safe and easy fuel storage

Some of diesel’s disadvantages are:

- Burns with notable by-products, including carbon in exhaust

- Noise factor, particularly in older model engines

- Higher initial purchase price

- Less reliable in extreme temperatures

- Harder to start in cold, more difficult to shut off in heat

- Fuel tends to contaminate easily

- More expensive initial purchase price

- Engines are usually bulkier and require more room to operate and store

- Diesel prices fluctuate considerably, especially with the seasons

Advantages of Natural Gas Generators

Although diesel fuel and gasoline engines have been the traditional choice for power generation systems, natural gas as fuel alternative is becoming increasingly popular. That’s due to technological advancements and an evolving supply grid for natural gas distribution.

Natural gas internal combustion engines work on the same ignition principle as gasoline models. Natural gas as a vapor is injected right into the combustion chamber and ignited by a spark plug and distributor wiring system. Natural gas burns in the cylinder, and the exhaust is piped out into the atmosphere. There are few harmful emissions, and it’s considered the cleanest-burning fossil fuel available.

Distribution and storage of natural gas has its limitations. Most applications for natural gas generators are in close proximity to urban areas, where the pressurized gas pipelines are established. Otherwise, natural gas has to be trucked in with specialized containers and stored at the generator location in high-strength containers.

Many natural gas generators are used right at natural gas production facilities where their fuel is tapped into the masthead. This is an economical, practical approach, but is limited to gas field application. In other areas, natural gas is not as popular even though its purchase cost per volume and return on energy density is excellent.

That’s simply due to the distribution and storage issues, not to the overall advantages and disadvantages of a natural gas vs. diesel vs. gasoline generator.

Some of natural gas’s advantages are:

- Extremely clean burning with limited pollutants

- Low cost per volume of gas consumption

- Good return on energy density and overall consumption

- Works well with conversions from gasoline engines

- No need for distribution and storage costs when piped into existing grid

- Low maintenance due to clean operating environment

- Not prone to spill cleanup

- Stable, relatively predictable fuel pricing

Some of natural gas’s disadvantages include:

- Not as popular as diesel and gasoline, therefore fewer models available

- Emerging technology challenges with unproven techniques

- Storage and handling costs if not piped-in

- Initial purchase of natural gas generators is high

- Considerable depreciation and lower resale value than diesel

- Less torque and horsepower capability than diesel

- Highly explosive substance when escaped from containment

Comparing Performance in All Three Types

As you can see, all three types of engines have their advantages and disadvantages. But how do they compare with each other in various performance categories? Let’s look at how gasoline, diesel and natural gas generators stack up in 12 different areas using performance ratings of low, medium and high.

Gasoline Generators

Gasoline powered generators perform best in extreme temperature environments. Their initial purchase cost is also attractive, but gasoline engines don’t stand up well in the long term compared to diesel and natural gas, nor are they as safe to operate due to fuel flammability.

- Purchase Cost — Low

- Depreciation — High

- Fuel Cost — Medium

- Energy Density — Low

- Durability — Low

- Reliability — Low

- Noise Factor — Medium

- Safety Factor — Low

- Fuel Availability — Medium

- Fuel Storage — Medium

- Emissions — Medium

- Extreme Temperature Performance — High

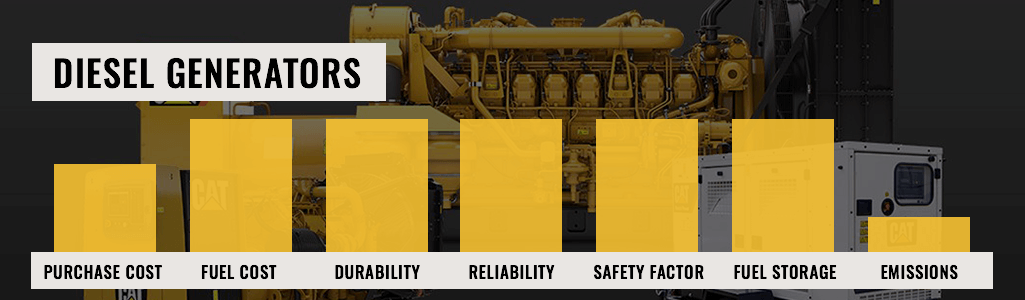

Diesel Generators

Diesel engine generators are considered the best overall performers, especially in fuel efficiency and dependability. Diesel is the safest fuel source, the widest available and stores well. However, the noise and emission factors place diesel behind gasoline and natural gas.

- Purchase Cost — Medium

- Depreciation — Low

- Fuel Cost — High

- Energy Density — High

- Durability — High

- Reliability — High

- Noise Factor — Low

- Safety Factor — High

- Fuel Availability — High

- Fuel Storage — High

- Emissions — Low

- Extreme Temperature Performance — Low

Natural Gas Generators

Natural gas engines are the cleanest burning and have the lowest fuel costs of the three generator types. They’re middle of the road in holding value, reliability and safety. Natural gas in the United States is fairly abundant and relatively cost-efficient

- Purchase Cost — High

- Depreciation — Medium

- Fuel Cost — Low

- Energy Density — Medium

- Durability — Medium

- Reliability — Medium

- Noise Factor — Low

- Safety Factor — Medium

- Fuel Availability — Medium

- Fuel Storage — Low

- Emissions — High

- Extreme Temperature Performance — Medium

Emerging Generator Technology

Technology is advancing all the time, and new types of generators are introduced to the market on an ongoing basis. Here are a couple of emerging technologies to be aware of and consider for your generator choice.

Gasoline powered the first internal combustion generator engine. It evolved into a diesel model and later into one powered by natural gas. Like all inventions that prove their worth, generators continue to evolve in many ways, too.

Next-generation generators use advanced computer controls for their operation and monitoring systems. More sophisticated materials extend generator service life and reduce maintenance requirements. This leads to less downtime and an increase in productivity. This is all good for consumer investment.

Hybrid and Biofuel Generators

One of the most interesting breakthroughs in generator design and operation is new forms of fuels and hybrid blending of current systems. Hybrid by definition means to bring two items together to serve a common purpose. With generators, that should include more efficient machines that produce electrical power with less expense.

Experimentation in the hybrid blending of gasoline and natural gas fuels works on the principle of starting the generator with gasoline, which is better at boosting energy. As the generator gets up and running, the fuel supply is replaced with a steady flow of natural gas, which is more efficient and less costly.

After the initial purchase cost of a generator, your next-biggest bill is going to be fuel. The cost of fossil fuel is going to continue to rise despite the identification of new domestic sources and improved methods of distribution.

Biofuels are an excellent example of new technology being put to use in generators. Biodiesel is a blend of conventional diesel fuel and other combustible organic products such as vegetable matter. Bi-fuel is another hybrid energy provider that works with diesel having natural gas injected into the air intake system for added economy.

Browse Dynamic Gas Blending Systems

There are promising things to come in the future of power generation systems and lots of options for you to choose from. Knowing the advantages and disadvantages of the three main fuel sources should be part of your considerations when choosing a generator. There are other factors to consider.

Other Factors to Consider When Choosing a Power Generation System

The foremost consideration you need to assess is exactly what purpose your generator will serve. The second consideration is how much you’re prepared to pay for it. We’ll set your purpose and budget aside because you probably have these two issues identified before looking into these finer factors to consider, such as:

- Generator size. This is rated in KiloWatts for most and in MegaWatts for huge applications. It’s best to discuss the actual sizing with a professional generator supplier. In most cases, commercial and industrial applications require diesel or natural gas units to satisfy their wattage needs.

- Reliability. You need to be assured your generator comes from a reputable supplier that has a proven record of performance as well as servicing. Also consider the option of an integrated emergency power system.

- Warranty. Your brand selection should be made after looking at how comprehensive and reliable the coverage is.

- Maintenance. Selecting a low-maintenance generator will save you a lot of downtime. Good generator manufacturers like Caterpillar® have excellent service packages as well as providing reliable machines with excellent warranty.

- Safety. Your generator needs to run safely. That includes emitting low noise, being low in fire-risk and designed so nearby workers are not exposed to heat and moving parts. Talk to your Cat® dealer about the safety features built into every Cat power generation system.

Consider Cat Your Power Generation System Provider

Cat is the world’s most recognized brand when it comes to providing heavy-duty equipment, including the best diesel and natural gas powered generators. The Caterpillar name is synonymous with quality, dependable and versatile equipment.

Warren CAT is an authorized Cat dealer providing power generation systems throughout West Texas and Oklahoma. We’ve dedicated our business to providing customers with complete solutions to all heavy equipment, including generators.

Contact us today or give us a call at 866-292-7736 to talk to us about the power solutions that will serve you best. We’re happy to guide you and help you make the right choice. Trust Warren CAT for clean, continuous power.