938M Small Wheel Loader

Engine

- Maximum Gross Power

- 188HP

- Maximum Net Torque - ISO 9249:2007 (Performance Power Mode: Range 1-4)

- 650ft·lbf

- Maximum Net Torque - ISO 9249:2007 (Standard Power Mode: Range 1-3*)

- 628ft·lbf

- Rated Net Power - 1,800 rpm - ISO 9249 at Minimum Fan Speed (Performance Power Mode: Range 1-4)

- 184HP

- Displacement (Performance Power Mode: Speed Range 1-4)

- 427in³

- Displacement (Standard Power Mode: Speed Range 1-3*)

- 427in³

- Maximum Gross Power - 1,600 rpm - ISO 14396 (DIN) (Standard Power Mode: Range 1-3*)

- 176mhp

- Note (3)

- **The Cat C7.1 ACERT engine meets Tier 4 Final/Stage V off-highway emission standards.

- Note (2)

- *Range 4 power and torque is equal to Performance Mode with Caterpillar Power by Range technology.

- Rated Net Power - 1,600 rpm - ISO 9249 at Minimum Fan Speed (Standard Power Mode: Range 1-3*)

- 170HP

- Note (1)

- Net power ratings are tested at the reference conditions for the specified standard and denote power available at the flywheel when the engine is equipped with alternator, air cleaner, emission components and fan at specified speed.

- Engine Model

- Cat C7.1 ACERT**

- Maximum Rated Gross Power - Maximum Engine Speed (Performance Power Mode: Range 1-4)

- 1800r/min

- Rated Net Power - 1,800 rpm - SAE J1349 at Minimum Fan Speed (Performance Power Mode: Range 1-4)

- 183HP

- Rated Net Power - 1,800 rpm - ISO 9249 (DIN) at Minimum Fan Speed (Performance Power Mode: Range 1-4)

- 186mhp

- Maximum Gross Torque - ISO 14396 (Performance Power Mode: Range 1-4)

- 664ft·lbf

- Maximum Net Torque - SAE J1349 (Performance Power Mode: Range 1-4)

- 649ft·lbf

- Maximum Rated Gross Power - Maximum Engine Speed (Standard Power Mode: Range 1-3*)

- 1600r/min

- Rated Net Power - 1,600 rpm - SAE J1349 at Minimum Fan Speed (Standard Power Mode: Range 1-3*)

- 170HP

- Rated Net Power - 1,600 rpm - ISO 9249 (DIN) at Minimum Fan Speed (Standard Power Mode: Range 1-3*)

- 172mhp

- Maximum Gross Torque - ISO 14396 (Standard Power Mode: Range 1-3*)

- 642ft·lbf

- Maximum Net Torque - SAE J1349 (Standard Power Mode: Range 1-3*)

- 627ft·lbf

- Maximum Gross Power - 1,800 rpm - ISO 14396 (Performance Power Mode: Range 1-4)

- 188HP

- Maximum Gross Power - 1,800 rpm - ISO 14396 (DIN) (Performance Power Mode: Range 1-4)

- 190mhp

- Maximum Gross Power - 1,600 rpm - ISO 14396 (Standard Power Mode: Range 1-3*)

- 173HP

Weights

- Operating Weight

- 35778lb

Buckets

- Bucket Capacities

- 2.5-5.0 m3 (3.2-6.5 yd3)

- Bucket Capacities - General Purpose

- 2.5-3.2 m³ (3.2-4.2 yd³)

- Bucket Capacities - Light Material

- 3.1-5.0 m³ (4.0-6.5 yd³)

Cab

- ROPS

- ISO 3471:2008

- FOPS

- ISO 3449:2008 Level II

- Note (3)

- *The measurements were conducted with the cab doors and windows closed and at 70% of the maximum engine cooling fan speed. The sound level may vary at different engine cooling fan speeds.

- Note (2)

-

The declared dynamic operator sound pressure levels per ISO 6396:2008*, when properly installed and maintained, are:

– Standard cab: 68 ±3 dB(A)

– Deluxe cab: 66 ±2 dB(A) - Note (1)

- Cab and Rollover Protective Structures (ROPS) are standard in North America and Europe.

Loader Hydraulic System

- Maximum Flow - Implement Pump - 3rd Function Maximum Flow*

- 50gal/min

- Hydraulic Cycle Time - Standard Mode at 1,600 rpm - Float Down, Maximum Lift to Ground Level

- 2.7s

- Hydraulic Cycle Time - Performance Mode at 1,800 rpm - Float Down, Maximum Lift to Ground Level

- 2.7s

- Hydraulic Cycle Time - Standard Mode at 1,600 rpm - Raise, Ground Level to Maximum Lift

- 6.2s

- Relief Pressure - Tilt Cylinder

- 4351psi

- Maximum Working Pressure - Implement Pump

- 4061psi

- Maximum Flow - Implement Pump

- 50gal/min

- Maximum Flow - Implement Pump - 4th Function Maximum Flow*

- 42gal/min

- Relief Pressure - Tilt Cylinder - 3rd and 4th Function Maximum Working Pressure

- 4061psi

- Relief Pressure - Tilt Cylinder - 3rd and 4th Function Relief Pressure

- 4351psi

- Note (1)

- *3rd and 4th function flow is fully adjustable from 20% to 100% of maximum flow through the secondary display, when equipped.

- Hydraulic Cycle Time - Performance Mode at 1,800 rpm - Dump, at Maximum Lift Height

- 1.5s

- Hydraulic Cycle Time - Standard Mode at 1,600 rpm - Dump, at Maximum Lift Height

- 1.7s

- Hydraulic Cycle Time - Standard Mode at 1,600 rpm - Total Cycle Time

- 10.6s

- Hydraulic Cycle Time - Performance Mode at 1,800 rpm - Total Cycle Time

- 9.7s

- Hydraulic Cycle Time - Performance Mode at 1,800 rpm - Raise, Ground Level to Maximum Lift

- 5.5s

Steering

- Steering Cycle Times - Full Left to Full Right - At 1,800 rpm: 90 rpm Steering Wheel Speed

- 2.3s

- Maximum Working Pressure - Steering Pump

- 3500psi

- Maximum Steering Torque - 0° (Straight Machine)

- 42506ft·lbf

- Maximum Flow - Steering Pump

- 34gal/min

- Maximum Steering Torque - 40° (Full Turn)

- 31398ft·lbf

- Number of Steering Wheel Turns - Full Left to Full Right or Full Right to Full Left

- 3.3turns

- Steering Articulation Angle - Each Direction

- 40°

Tires

- Note (3)

- Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model.

- Other Choices Include

- 20.5 R25, radial (L-2); 20.5 R25, radial (L-5); 20.5-25 12PR (L-2); 20.5-25 12PR (L-3); 20.5-25 16PR (L-5); 23.5 R25, radial (L-3); 650/65 R25 radial (L-3); Skidder/Agriculture; Solid Tires

- Note (2)

- In certain applications, the loader’s productive capabilities may exceed the tire’s tonnes-km/h (ton-mph) capabilities.

- Standard Size

- 20.5 R25, radial (L-3)

- Note (1)

- Other tire choices are available. Contact your Cat dealer for details.

Axles

- Front

- Fixed; Locking differential (standard)

- Rear

- Oscillating ±11 degrees; Open differential (standard); Limited slip differential (optional)

Service Refill Capacities

- Note

- DEF used in Cat SCR systems must meet the requirements outlined in the International Organization for Standardization (ISO) standard 22241-1.

- Transmission - Gear Box

- 2.9gal (US)

- Engine Crankcase

- 5.3gal (US)

- Fuel Tank

- 51.5gal (US)

- Diesel Exhaust Fluid (DEF) Tank

- 5gal (US)

- Front Axles

- 9.2gal (US)

- Rear Axles

- 9.2gal (US)

- Hydraulic System - Including Tank

- 44.9gal (US)

- Cooling System

- 7.9gal (US)

- Hydraulic Tank

- 23.8gal (US)

Transmission

- Note

- *Creeper control allows maximum speed range adjustability from 1 km/h (0.6 mph) to 13 km/h (8 mph) in Range 1 through the secondary display, when equipped. Factory default is 7 km/h (4.4 mph).

- Forward and Reverse - Range 1*

- 1-13 km/h (0.6-8 mph)

- Forward and Reverse - Range 2

- 8mile/h

- Forward and Reverse - Range 3

- 17mile/h

- Forward and Reverse - Range 4

- 25mile/h

Air Conditioning System

- Air Conditioning

- The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.9 kg of refrigerant which has a CO2 equivalent of 2.717 metric tonnes.

Sound

- Note (1)

- European Union Directive “2000/14/EC”

- Average Exterior Sound Pressure (ISO 6395:2008)

- 101dB(A)

- Operator Sound Pressure (ISO 6396:2008)

- 72dB(A)

Sustainability

- Recyclability

- 94%

Efficiently Powerful

- Saves fuel and reduces cab sound levels

- Biggest gains are seen during load and carry, snow removal and roading applications

- Enabled at the push of a button (HP+), boosts engine power by up to 10% and engine speed by over 12%

- Increases hydraulic cycle times and productivity

The Cat® C7.1 engine provides cleaner, quieter operation while delivering superior performance and durability through a high torque, low speed design. Caterpillar's exclusive Intelligent Power Management system monitors operator input and power availability to keep the machine working at peak efficiency and provide the operator with greater customization to suit their application.

A choice of Power Modes allows you to choose between maximum fuel efficiency or boosted power along with hydraulic speed.

STANDARD POWER MODE

PERFORMANCE POWER MODE

Lock up and go with fully locking front differential axle that can be engaged on the move at full torque. Maximize your traction with optional Limited Slip Differential on the rear axle to keep you climbing.

Work Made Easy

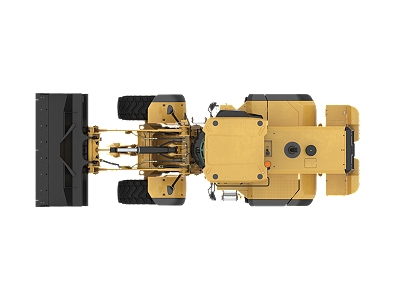

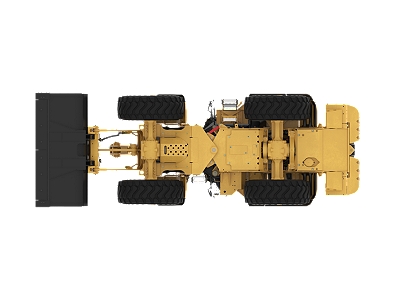

OPTIMIZED Z-BAR LINKAGE

The optimized Z-bar linkage combines the digging efficiency of a traditional Z-bar with integrated tool carrier capabilities for great performance and versatility. Visibility to bucket corners and fork tips at ground level remain excellent while sight lines at maximum lift are improved with a Generation III lift arm design. Lift higher and reach further with optional High Lift linkage available on all three models.

QUICK LOADING PERFORMANCE SERIES BUCKETS

Performance Series Buckets deliver up to 10% higher fill factors compared to previous models, better material retention for significant productivity and fuel efficiency improvements. The buckets feature a longer floor to take a bigger bite of the pile, an open throat to heap higher and curved side bars to help with material retention.

Enjoy All Day Comfort

- Automatic climate control with heated rear glass and external mirrors

- Information at a glance with large primary LCD display

- Heated and cooled seat option

- Optional Ride Control

- Exclusive electro-hydraulic cylinder snubbing

- An extra eye on the job site with optional integrated rear object detection and optional* rearview camera

A spacious, quiet and comfortable operator environment helps keep you relaxed and productive throughout the day. Experience superior all around visibility with single piece front windshield, redesigned linkage and clean hydraulic lines routing. Seat-mounted controls featuring low effort joystick for lift and tilt functions along with integrated Forward/Neutral/Reverse switch, differential lock trigger and optional third and fourth auxiliary functions.

*Standard in Europe.

Customize Your Experience

- Select your Power Train Mode

- Reduce tire wear using Rimpull

- Fine tune ground speed with Creeper Control

- Adjustable Electo-Hydraulic Controls

- Set Directional Shift Response based on job application

The M Series Wheel Loaders will remember you and your personal settings with unique operator codes to make this machine truly yours and keep it secure.

Work as one with your machine by customizing your controls.

Service

- Product Link™ PRO standard with optional subscription to VisionLink®.

- Maintenance reminders through secondary display at scheduled intervals.

- Fit for Life Diesel Particulate Filter that is designed to exceed the engine overhaul life.

- Quick fuel filter service with Caterpillar's exclusive electric fuel priming pump.

- Jump start studs as standard equipment.

- Extended cleanouts with single plane cooling system and wide spaced 6 fans per inch coolers as standard.

- Integrated Autolube (optional) with adjustable greasing frequency.

Get up and running quickly with ground level, daily service access and optional engine compartment lighting. Three large service doors can be opened and closed in any order to give full access to filters and service points. Extended service intervals on hydraulic and power train filters reduce service time and maximize uptime. Additional service features include:

Customer Support

With renowned Cat dealer support, rely on your Cat dealer to help you every step of the way with new or used machine sales, rental or rebuild options to meet your business needs.

Maximize your machine uptime with unsurpassed worldwide parts availability, trained technicians and customer support agreements.

Let us earn your business. Experience an M Series Small Wheel Loader and join the Caterpillar family.

Sustainability

- The Cat® C7.1 engine meets U.S. EPA Tier 4 Final, EU Stage V and Korea Tier 5 emission standards.

- Engine Idle Management System (EIMS) helps maximize fuel efficiency and reduce greenhouse gas emissions while maintaining machine performance.

- Engine Idle Shutdown Timer reduces fuel burn, greenhouse gas emissions and unnecessary idle time by shutting down the machine after a pre-set idling period.

- Performance Series Buckets have rounded side boards, a longer floor and open angle to carry more and load quicker so each pass is the most efficient.

- Rimpull Control is a quick way to adjust the torque to the tires for less slipping and tire wear.

- Cat® Production Measurement provides real-time payload weighing which help you maximize productivity, reduce fuel burn and greenhouse gas emissions, all while improving job site efficiency and lowering costs.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine.

- Power on Demand, transparent to the operator, provides full-time efficiency and power when you need it.

- Tire Pressure Monitoring provides real-time tire pressure information to the operator to help increase tire wear and achieve better fuel efficiency and reduced greenhouse gas emissions.

- Intelligent Hystat Transmission helps improves control and reduces fuel consumption and greenhouse gas emissions in load and carry applications.

- Variable Displacement Pumps match power to load as application requirements change.