Tech Leadership for the Heavy Equipment Industry

Technology and data continually change the way the world works, even in industries dependent on heavy equipment and power systems like construction, oil and gas production, mining, landfill management, electric power generation and more. Every worksite or installation has the potential to generate incredible amounts of data which can hold the keys to working more efficiently and producing more while keeping operators and workers safe.

However, raw data alone is not enough. In order to unlock the full benefit and potential of the data generated from your projects and job sites, it has to be translated into meaningful, actionable intelligence.

With Warren CAT and Caterpillar®, you now have access to these cutting-edge data technologies specifically created and designed to support all industries that rely on heavy equipment, power systems and electric power generation. These technology offerings are leading the way for businesses to increase uptime while reducing operating costs, enhance and improve job site safety for people and equipment, monitor projects and manage fleets for greater efficiencies, all while helping to reduce environmental impact and simplify compliance reporting.

Call 866-292-7736, visit a Warren CAT location, or contact us online to discover how Caterpillar technology offerings can enhance and improve your day-to-day operations.

Equipment Management for a New Era

Harnessing and leveraging equipment data intelligently in combination with the industry-leading, world-class support of Warren CAT and Caterpillar for your equipment provides you with an unparalleled level of comprehensive equipment management.

Working hand-in-hand, these technologies and services are designed to help you better manage your assets while lowering operating costs. Equipment data can help boost work site productivity, efficiency and safety while also providing insights into potential health and maintenance issues including fuel burn and utilization, fluid contamination, total operating hours and equipment location. This data can help increase profitability by informing your fleet optimization and lifecycle planning as well as identifying needed services such as inspections, fluid analysis, maintenance and repairs.

Cat® SIS For Parts & Service

An online electronic parts and service reference tool, Caterpillar Service Information System (Cat SIS) provides detailed service information for Cat machines and products from 1977 up to today, including over 2 million service graphics, 1.5 million part numbers and 44,000 parts and service documents.

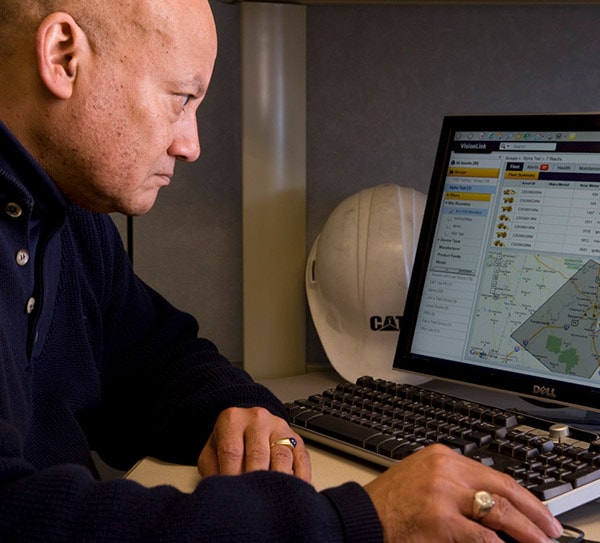

VisionLink®, Remote Fleet Vision (RFV) and Remote Asset Monitoring (RAM)

With easy-to-use web-based applications, these data tools utilize state-of-the-art implementations of GPS and cellular-based technology to collect, display and deliver your equipment data, enabling your business to monitor equipment operational data, health and key vital signs in near real-time from virtually anywhere.

Conditioning Monitoring

Equipment data and insights can help your business operations improve efficiencies and safety, reduce operating costs and identify service or repair needs. However, not all business operations have the benefit of routine monitoring of their heavy equipment fleet. For those operators, Warren CAT offers a revolutionary, comprehensive Conditioning Monitoring program designed to support your operations and ensure the long-term health of your equipment.

Customer Value Agreements

Combined with real-time equipment data insights, a Customer Value Agreement (CVA) is a powerful tool customers can use for planning routine maintenance that can help mitigate performance and operational issues while accounting for downtime and reducing operational costs that can occur with unplanned maintenance and repairs

S•O•SSM Fluid Analysis

Data in another form, S•O•S Fluid Analysis can help identify equipment issues that require maintenance or repair. Routine fluid analysis can also help reduce ownership and operational costs and improve equipment lifecycles by identifying potential problems early.

Contact Our Technology Division

_______________________________________________________________